The manufacturing and quality system of SUNKEAN high-quality fences | Sunkean.com

Our fence is made of iron (steel).The manufacturing factory is manufactured in Hebei Province, China, which is called the hometown of fences in China. We strictly control quality from material procurement to shipping. We have dedicated welding equipment, fully automatic dip coating production line, electrostatic powder coating production equipment, etc.

SUNKEAN Fence manufacturing flow

STEP.1 About cutting out the net

First, cut out the wire that will be the net of the main body from the roll-shaped steel wire that is the raw material for the fence.

STEP.2 Welding of net

Weld the wire to make the net body. Weld firmly according to the net pitch with a dedicated welding machine. Quality control is performed to prevent uneven welding and burrs.

STEP.3 Bending process

For strength, both ends of the net are bent into a half-round shape.

STEP.4 Surface treatment

SUNKEAN fence coating is mainly divided into three types: powder coated fence 、PVC coated fence and hot dip galvanized fence . Our products do not rust easily and its quality is stable.

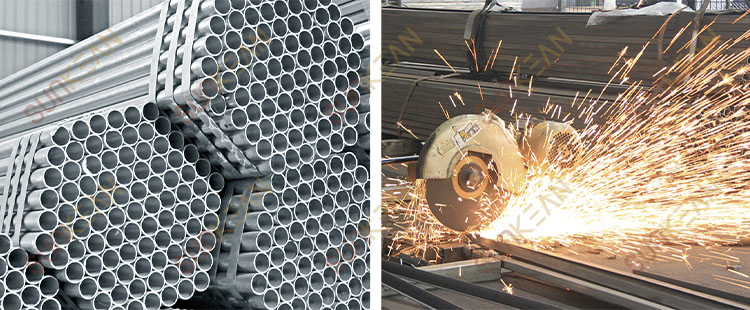

Post manufacturing flow

STEP.1 Cut

Cut the round pipe to the required length as shown in the drawing.

STEP.2 Drilling

Drill a hole in the round pipe to attach the fence.

STEP.3 Surface treatment

Like the mesh panel, it is mainly divided into three types: powder coated、PVC coated and hot dip galvanized.

Quality control / inspection flow

We thoroughly inspect the nets and columns for thickness and uneven coating.After inspection, it will be packed and shipped in a container.

Confirmation of product size and dimensions

Confirmation of the amount of plating / paint adhesion

Check the thickness of the material

Confirmation of wire diameter

We undertake thorough quality control and customized production of specifications to satisfy our customers.

评论

发表评论